BQUADRO After Sales

Service Transformation

Post-purchase After-sales | Digitalization

Digitize and automate key post-sales processes, turning a purchase into an opportunity to build an effective relationship with your customer at every stage of the product lifecycle, riding the wave of Servitization.

In fact, today more than ever, service is as important as the product.

As a result, organizations feel the need to reorganize to maintain their competitiveness, and every activity related to a sold unit contributes to shaping the perceived value by the buyer, especially in businesses with complex commercial and distribution networks spanning multiple levels

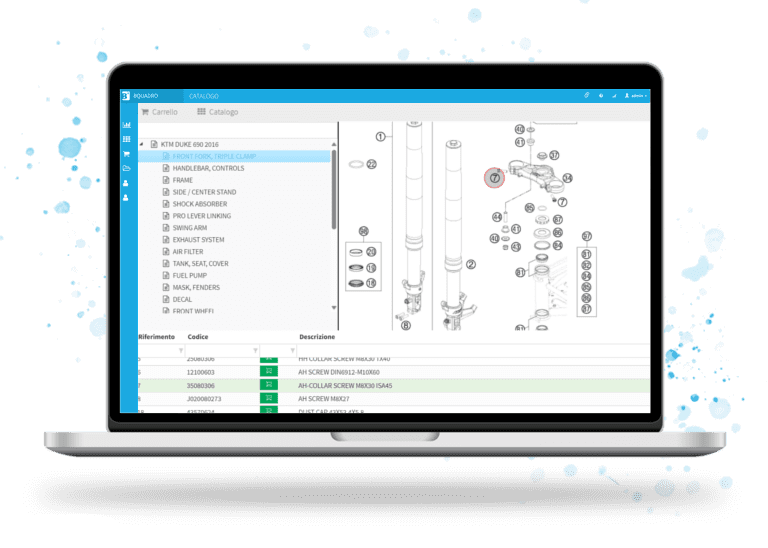

Spare Parts Management

Amaze your customers

Acquistare un ricambio non è mai stato così facile

Allow the end user to easily and precisely identify a spare part, even for complex or customized products.

Through a series of exploded view drawings, which is a navigable structure containing diagrams for a specific model and its accessories, your customer can order a spare part directly from the diagrams with just a few clicks.

Multiple codes can be linked to each spare part to identify alternative or replacement components. This way, the buyer can order a compatible item in case a specific component is not currently available or is out of production.

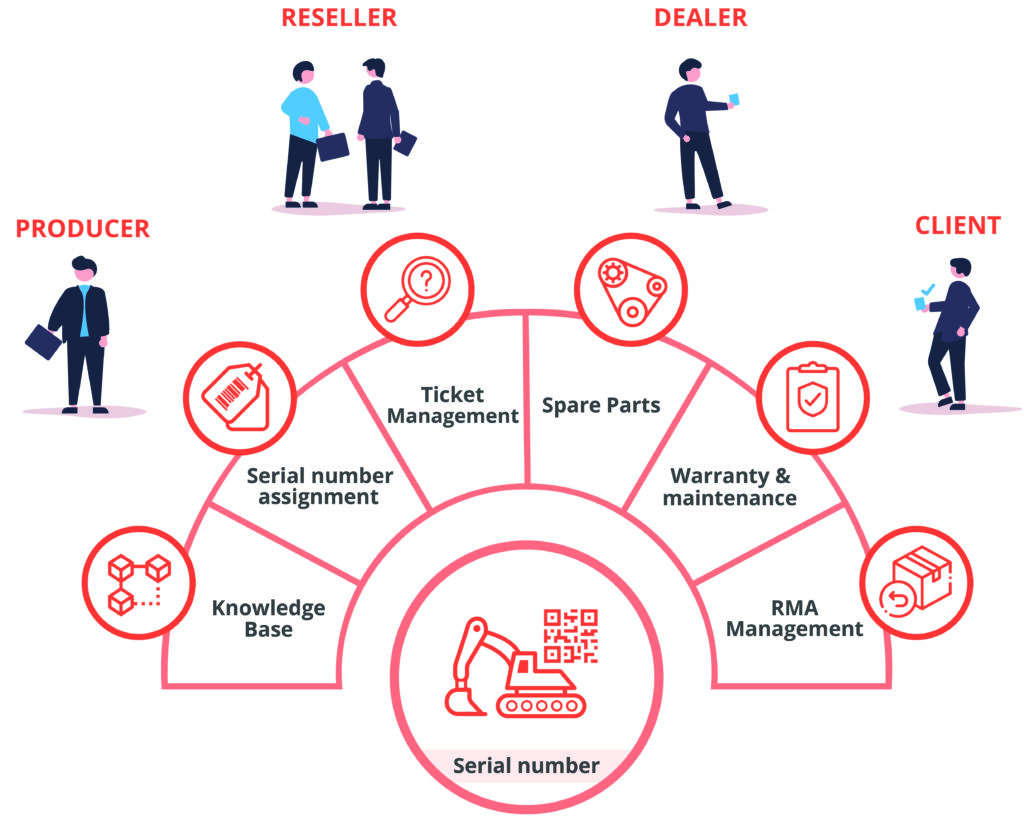

Serial Management

BQUADRO After Sales

Serial number

The key element around which all After Sales services revolve is the serial number, which is the identifier of a purchased product and, in certain contexts, can be detected through QR codes, barcodes, or RFID. Strategic information can be associated with the serial number, accessible from a single dashboard: details about the specific item, its release date, distinctive features, warranty contracts and their status, the list of performed maintenance, the presence of a maintenance plan, and the history of operators involved.

Knowledge base

Each serial number is equipped with a set of information useful for resolving various types of issues related to the purchased product: for the installer who needs to assemble the product, for the maintainer who needs to view technical sheets for maintenance purposes, and for the customer who needs to order a replacement part. The Knowledge Base consists of various types of information and documents, including guides, (video) tutorials, user manuals, technical specifications, FAQs, common issues, and specific documentation.

Serial number assignment

In businesses where the distribution network is particularly complex or layered across multiple levels, it is necessary to track all ownership transitions (if sold) or management transitions (if consigned) that the serial number undergoes in its lifecycle. This process begins with the manufacturer, then moves through the potential importer, distributor, retailer, until it reaches the transition to the dealer who ultimately sells the serial number to the end customer.

Ticket management

Thanks to the integration of specific software for the organized management of support tickets (e.g., Zendesk, Jira, and Uservoice), your customer can submit support requests through any channel. These requests are made available on the platform, where the user can find all the information and the history of requests. Furthermore, the platform can interact with ticketing systems, analyze all open requests, and, by associating them with a specific reference number, share all the relevant information on this channel for resolving the ticket.

Warranty & maintenance

Enable/disable warranties, manage complex warranty contracts, and the activation process from the platform. At any time, the parties involved in managing the serial number can view its status and expiration date. Set up a maintenance plan for each serial number. This way, your customer can perform scheduled maintenance regularly and systematically and manage any extraordinary maintenance in an organized and efficient manner, reducing and planning machine downtimes.

RMA Management

If anomalies cannot be diagnosed and resolved remotely, your customer can submit a return request through the platform. By digitizing the RMA processing flow, you can gather information and attachments, automatically generate files for the customer to print and include in the return package, and have constantly updated information through integration with the ERP and WMS systems. Each RMA may contain multiple lines identifying the returned components. Each line is managed with an independent processing flow, and the requester can view the real-time status of the submitted RMA through their dashboard associated with their identification number.